RisingSun Membrane is truly dedicated to serving theelectrocoating industry for Automotive & Appliance industry. We are a manufacturer, offering Ultrafiltration membrane, and Anolyte Cell technology for this important application. We are proud to have many engineers, sales, and service staff serving the e-coat industry.

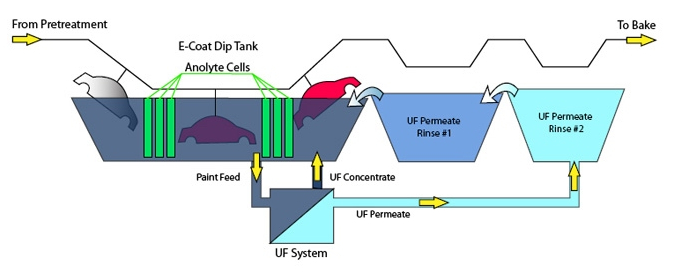

Ultrafiltration – Electrocoat painting is a process in which an object is dipped into a process tank and painted by means of Electrophoretic deposition. During the process, paint particles are suspended within a liquid medium and have a charged placed upon them. Under a high voltage DC current, the paint particles migrate to the part being painted and are deposited onto the surface, resulting in a highly corrosive resistant and durable paint film. The part is then rinsed several times, and the rinse water counter flows back to the main paint tank. Ultrafiltration must be used to remove the excess rinse water in the paint bath and balance the chemistry of the tank for a successful operation.

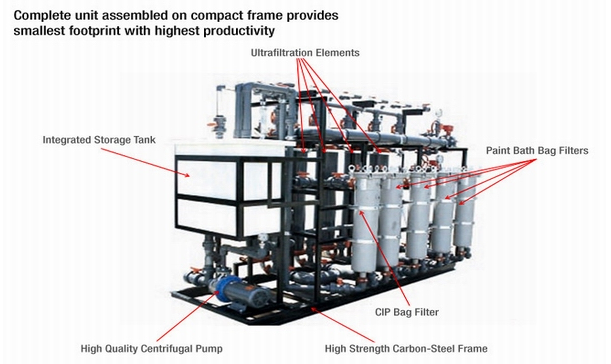

RisingSun Membrane is the manufacture of UF membrane, which can be used for E-COAT system. Contact Us to find out the detail info with the competitive price.

Ultrapure Water for Final Rinse – Reverse Osmosis systems are the preferred method for producing Ultrapure water for final rinse stages of electrocoating. RisingSun Membrane’s Reverse Osmosis Systems offer technologically advanced features at exceedingly affordable prices.

RisngSun Membrane’s Reverse Osmosis systems feature:

a. Up to 60% energy savings over traditional RO systems

b. Touch Screen HMI Control Panel & PLC’s are powerful yet easy-to-use

c. Stainless Steel frames are standard on all models

d. Our professional service team will be there for you years after your system is commissioned

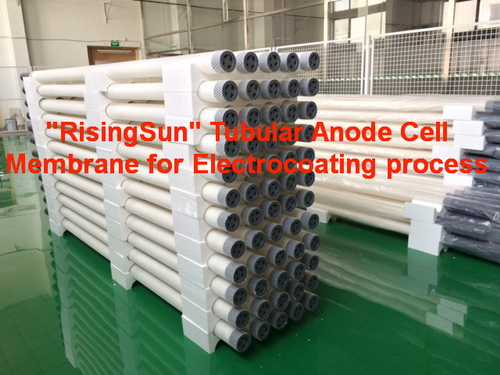

RisingSun Membrane offers Tubular Anolyte Cells systems to meet your electrocoating needs.

Anolyte Cells – Anolyte Cells are a crucial component in Cathodic Electrocoat painting. Excess acid is released during the deposition process, which must be removed at a steady rate to keep the paint chemistry in balance. Anolyte Cells (or Membrane Electrodes) remove the acid via a positively charged anionic (or “selective”) membrane located in the shell of the anolyte cell. The Anolyte Cell also houses a positive electrode (anode) that drives high voltage DC current to the part being painted (cathode).

Tubular Anode Cell provides a better paint coverage than flat cells due to a greater electrical “throw angle”. The anionic membrane area is greater than the anode area, reducing electrical resistance and therefore, lowering operational cost. RisingSun Membrane’s anolyte delivery system supplies maximum flushing of the anode to remove corrosive oxygen, extending anode life.

Contact us to find out the detail info with the competitive price.

info@risingsunmem.com