| SMBR Introduction |

|

|

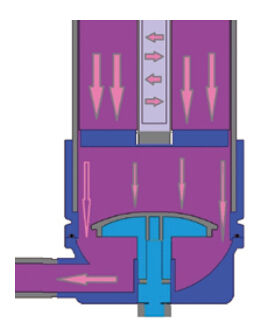

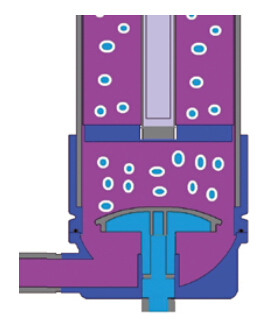

SMBR is a submerged backwashable spiral membrane, which is used in the field

of industrial wastewater and other processes. SMBR is a innovative product which

can implement washing flow from the permeate carrier side with certain pressure.

Submerged systems rely on centrifugal pumps to generate a slight vacuum pulling

water through the membrane barrier layer. At the same time, its backwashing

frequency is the same as hollow fiber membrane. |

|

|

|

|

|

|

|

Features Air scour can decrease the pollutant deposition on membrane surface Open flow channels allows a worse feed quality Both submerged and split-type are acceptable with small field area Frequent backwashing is allowable The equipment investments and energy costs are lower |

|

|

|

|

|

|

|

|

|

|

Applications Industrial wastewater reuse RO pretreatment Landfill leachate pretreatment Domestic wastewater reuse |

Secondary sedimentation effluent Removal of heavy metals Process water Recycled water |

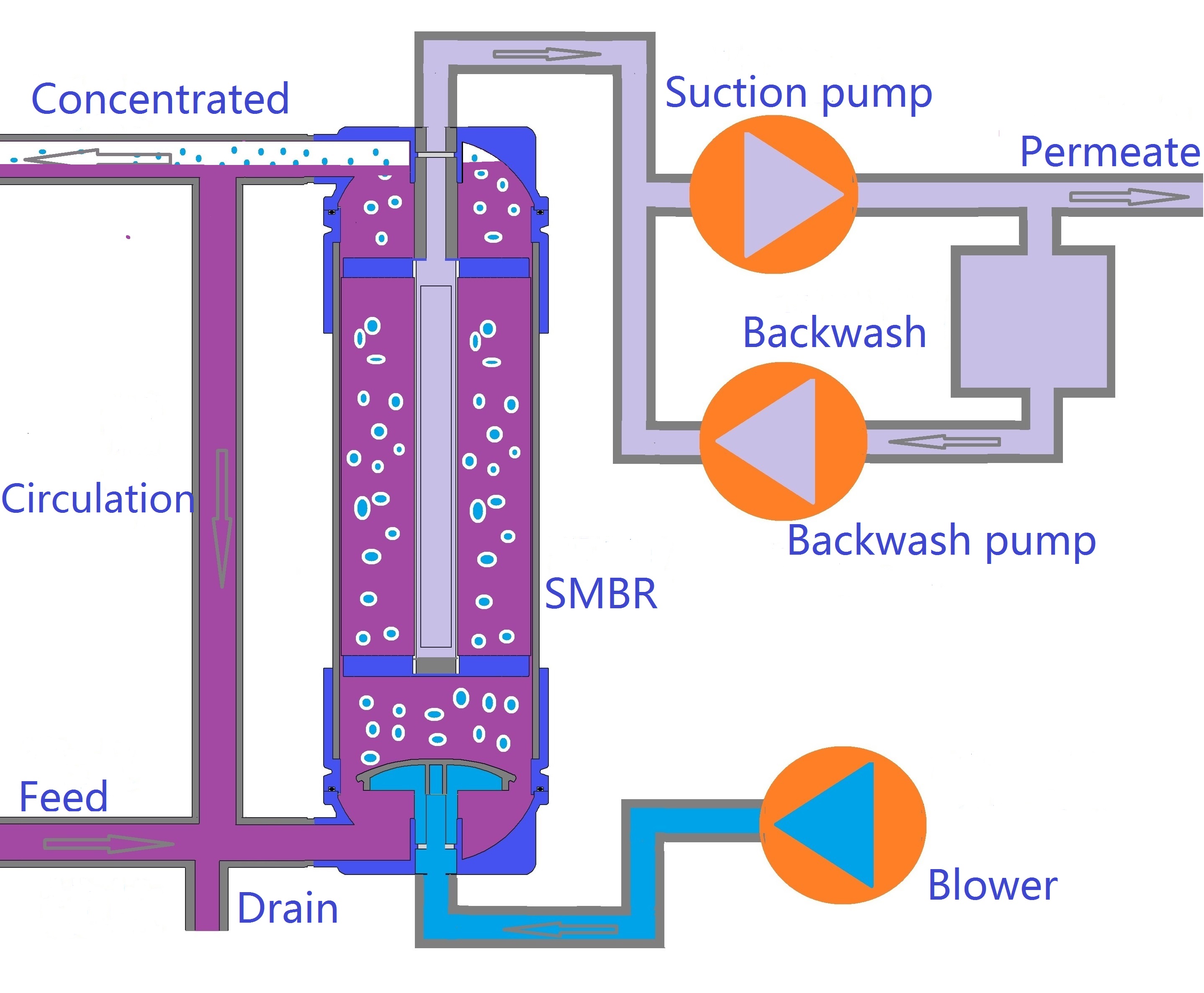

System flowchart

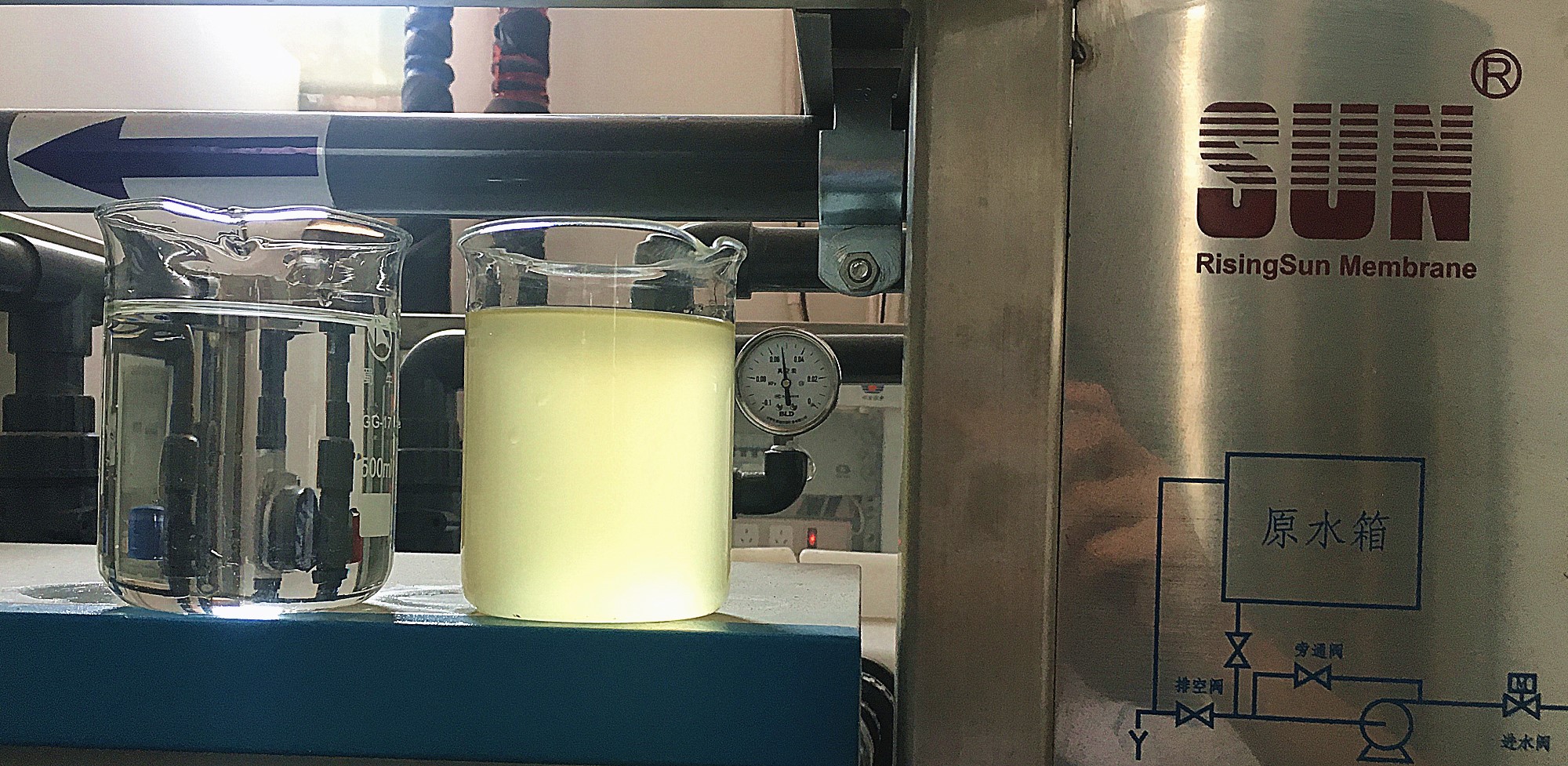

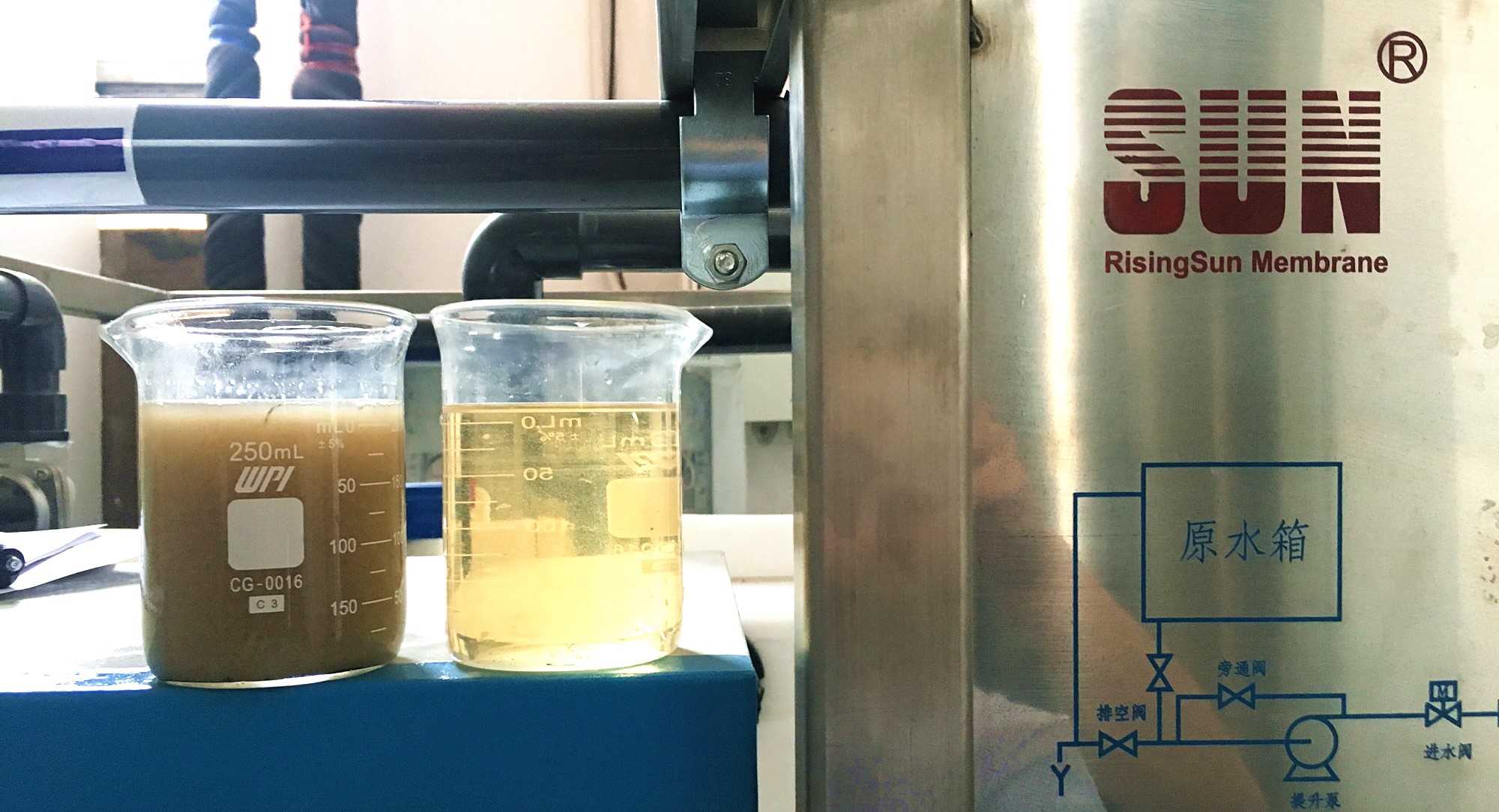

Testing machine

| Comparison of SMBR and Hollow fiber membrane | |

|

Identical |

Difference |

| Frequent backwashing |

SMBR has lower energy costs |

| Lower feed quality requirement |

SMBR has no risk of filament break |

| High recycle rate |

SMBR has open channels to prevent soild deposition |

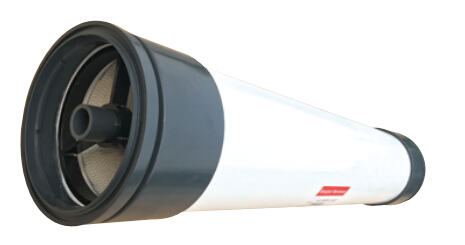

SMBR-10040 Specifications

SMBR-10040 Membrane element

Items

Completed with

vessel & caps

Membrane body only

![]()

![]()

Model

SP-SMBR-10040

SG-SMBR-10040

Membrane effective area (m2)

27.6

27.6

Diameter (mm)

250

250

Membrane materia

PVDF

PVDF

Membrane pore size (μm)

0.1

0.1

TMP range (bar)

0.1-0.7

0.1-0.7

Configuration

Split-type

Submerged

Operation Pressure

Positive

pressure (bar)

1.0

0.5

Negative

pressure (bar)

0.7

0.7

Permeate flux (L/H)

400-1000

400-1000

pH (continuous)

2-11

2-11

pH (cleaning)

2-11.5

2-11.5

Air flow rate[l /( min·pc )]

100

100

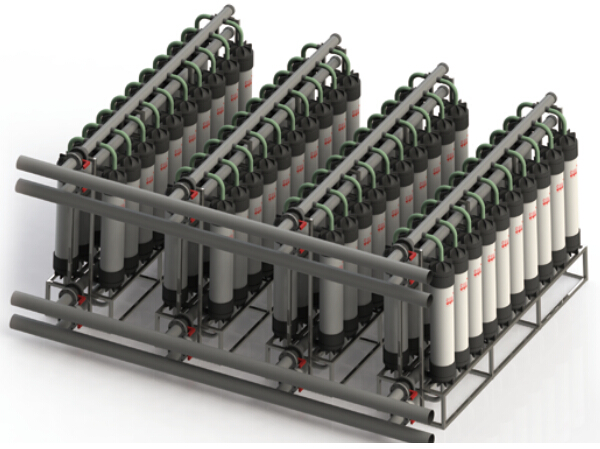

SMBR-10040 Membrane module

| Items |

SMBR-10040-20 |

SMBR-10040-40 |

SMBR-10040-80 |

|

Element qty. (pc) |

20 | 40 | 80 |

|

Membrane effective

area (m2) |

520 | 1040 | 2080 |

|

Permeate flux (m3/h) |

8-18 | 16-35 | 32-70 |

|

Size (mm) |

3000×850×1900 |

3000×2500×1900 |

3000×5800×1900 |

|

Weight (kg) |

700 | 1400 | 2800 |

|

Pipe materia |

PVC | PVC | PVC |

|

Feed flux (m3/h) |

10-22 | 20-42 | 38-80 |

|

Air flow rate[l /( min·module )] |

2000 | 4000 | 8000 |