|

Tubular Membranes Technology |

|

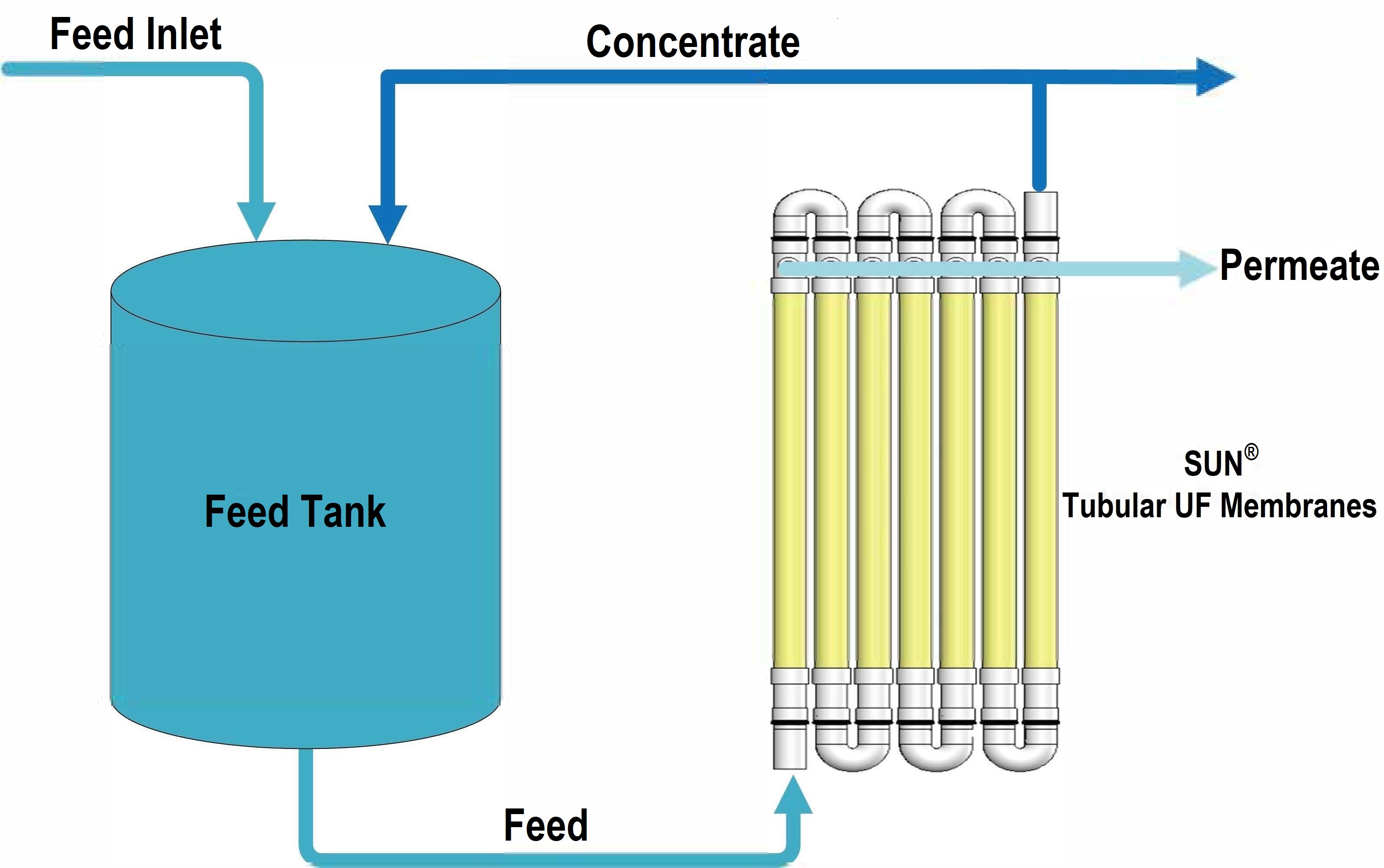

Tubular membranes are particularly suited to liquid with high viscosity or suspended solids, because their wide flow paths make them highly resistant to clogging. Tubular membranes system is an external and separated filtration system. For high solid content and viscosity liquid, we use adjustable cross-flow velocity to make the membrane run under optimal conditions and extend membrane service life. At the same time, it has more convenient cleaning, maintenance, and operation under closed pipeline.

SUN® Tubular membranes use a cross-flow filtration technology. The cross-flow filtration can reduce cleaning times and downtime, so as to maintain a high flow rate. Some membranes are available for back washing, if necessary, you can also use permeate or chemical cleaner for back washing, effectively extend the membranes working life.

Membranes Development

Membrane chemical materials:PVDF、PES、PAN、PS

MWCO range:5,000-250,000 Dalton

Membrane inner tube diameter:5-12.7mm

Membrane module standard diameter:3", 4", 6", 8",10". Standard length:3m, 3.6m, 4m

For pilot testing module standard diameter: 1~3", Length: 0.5~1.5m

We continue membrane chemical properties development to expand the range. Now, we can offer robust, fouling resistance and antioxidant membrane (PVDF Max. Chlorine Exposure 250,000ppm.h), acid and alkali resistance (20%NaOH), Pure water flux can be 800LMH, Max. operation pressure is10bar and max. temperature is 95℃.

Even if the activated sludge concentration up to 40g/L, the membrane flux can be 70~150LMH for domestic waste water.

Typical Applications

Difficult waste water fields:

Landfill leachate pretreatment

Pretreatment for alkali liquor recycle

Special chemical waste water (Coking, Tannery, textile, wood pulp bleach) treatment

Return injection of produced water from oil field

Emulsified oil treatment

Specialty fields:

Fruit juice and tea drinks clarification

Food and bio-pharmaceutical fermentation clarification

Electrophoretic paint recovery

Decoding of SUN® Tubular Membranes Model

Hydrophilic membrane sheet specifications:

Note: Membrane inner tube diameter is 5-12.7mm; Superior fouling resistance; Higher sustainable flux; Easier cleaning; Strong negative pressure resistance. Maximum operating pressure up to 10bar, Working life up to more than 5 years.